System Function:MCD Survey

![]() Instruction > Edit and Reply > MCD Survey

Instruction > Edit and Reply > MCD Survey

Edition : Supply Chain Platform – Lite; Supply Chain Platform – Basic

Information

MCD stands for Material Composition Declaration, consisting of the Certification of Compliance, Composition Datasheet and Test Report. Buyer issued the MCD Survey to suppliers for Green Product data collection.

You will learn how to search for certain MCD Survey according to certain conditions, manage and renew the data, and export the report following the instructions below.

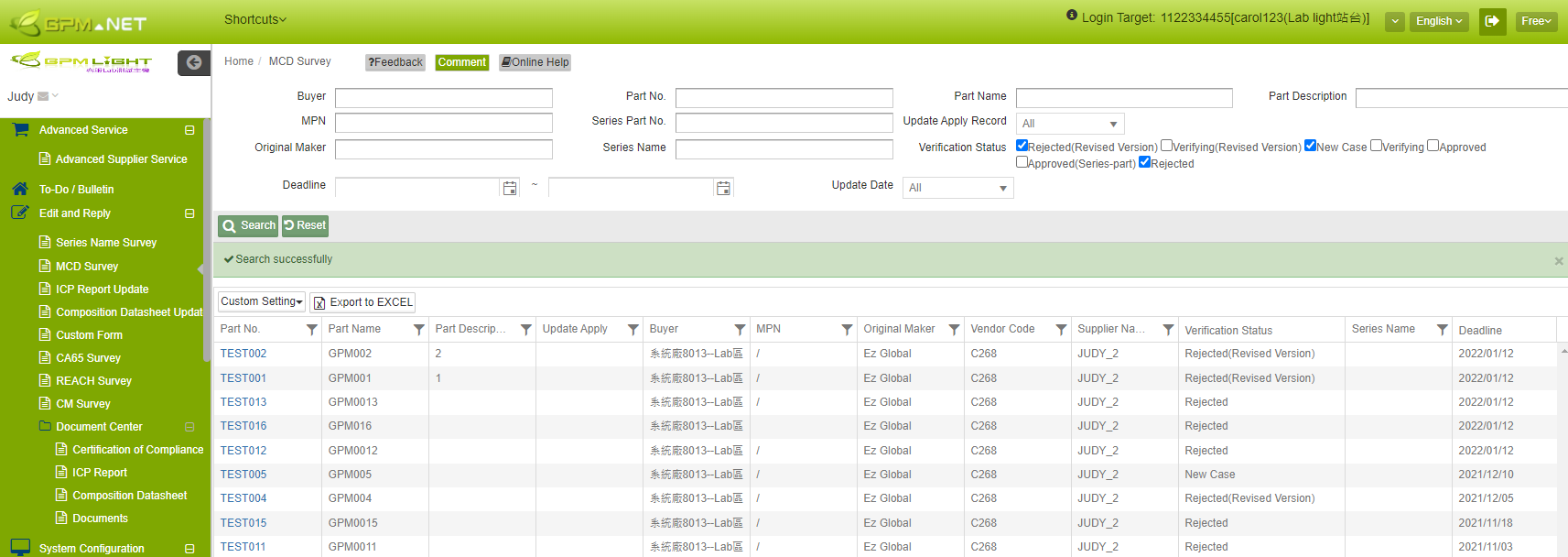

Main Page - Searching Columns

Searching Condition

You may search for certain MCD Survey by setting different conditions. The instructions are as follows:

| Column | Description | Remark |

|---|---|---|

| Buyer | The buyer's name. | Suppliers will be able to distinguish different buyers' names should you there are multiple forms/surveys from different buyers on this platform. |

| Part No. | Also known as IPN. It is an identifier of a particular part design used in a particular industry and should be the same as that of ERP's. | |

| Part Name | Part Name, which is usually the same as ERP's. | |

| Part Description | Part Description, which is usually the same as ERP's. | |

| MPN | Manufacturer Part Number, a manufacturer-assigned number which is used to identify a product among other products from the same manufacturer. | |

| Series Part No. | A Series Part Number is a part number which is assigned among other part numbers while a series is set. | |

| Original Maker | The maker of the part. | |

| Series Name | Same type of the part with same raw materials are series-part. Suppliers may set them as [Series] and set a [Series Name]. | |

| Verification Status | The Verification Status of the MCD Survey. There are currently 7 types of the Verification Status. | For Verification Status definition, please check: Verification Status. |

| Reply Deadline | A deadline calculated according to [Vendor Notification Settings]. (Should reply within X days after issued/reissued date; Should reply within Y days after rejection date; Document can be renewed Z days before expiration date.) Example: 2019/4/10 | |

| Update Date | The last modified time. |

Verification Status

There are currently 7 types of the Verification Status for MCD Survey:

- New Case: The newly issued MCD Survey from Buyer.

- Verifying: The MCD Survey completed and submitted by supplier.

- Approved: The MCD Survey approved by the buyer.

- Approved(Series-part): The MCD Survey approved by buyer based on the series part.

- Rejected: The MCD Survey rejected and returned to supplier by buyer after verification.

- Rejected(Revised Version): The new version of the MCD Survey issued and returned back to supplier for investigation.

- Verifying(Revised Version): The new version of the MCD Survey completed and submitted by supplier.

You may search for all types of the Verification Status by selecting none/all of the boxes, or select the ones needed.

Click the  button to search, or the

button to search, or the ![]() button to reset all settings.

button to reset all settings.

Searching Results

For the searching results presented in the table below, you may:

- Click on the title of the selected field to sort by particular order.

- Use the filter

to search for specific data.

to search for specific data. - Click

to export the searching results in a excel format.

to export the searching results in a excel format.

MCD Survey Columns and Description

Button Description

| Button Name | Description | Remark |

|---|---|---|

| Exit | Exit the current page. | |

| Copy | Copy the MCD Survey. | |

| Save | Save the data. | |

| Submit | Submit the MCD Survey. |

1. Basic Info.

| Column | Description | Remark |

|---|---|---|

| Part No. | Also known as IPN. It is an identifier of a particular part design used in a particular industry and should be the same as that of ERP's. | |

| Part Name | Part name, which is usually the same as ERP's. | |

| Part Description | Part Description, which is usually the same as ERP's. | |

| MPN | Manufacturer Part Number, a manufacturer-assigned number which is used to identify a product among other products from the same manufacturer. | |

| Original Maker | The maker of the part. | |

| Vendor Code | The code for the supplier. | |

| Supplier Name | Supplier Name. | |

| Green Policy | The Green Policy that the MCD Survey is required to follow. | Click the policy name to view all. |

| Series Part No. | A Series Part Number is a part number which is assigned among other part numbers while a series is set. | Click [View all Series-part No.] to see all Part No. |

| Supplier Memo | Extra information suppliers may provide to buyer. | |

| Previous Supplier Memo | Previous extra information suppliers provided to buyer. | Read-only |

| Verification Statement | Verification Statement provided by buyer(verifier). | Read-only |

2. Upload Certification of Compliance

The source of the Certification of Compliance referenced in the column is from Document Center-Certification of Compliance.

| Column | Description | Remark |

|---|---|---|

| Verification Status | The verification status of the certification of compliance. | |

| Document Title | The document title of the certification of compliance. | |

| Declaration Scope | The declaration scope of the certification of compliance, such as RoHS, REACH, Declaration of Compliance etc. | |

| Required | The requirement of the certification of compliance: Yes or No. | |

| Template | The template will be displayed here should the buyer have provided one. Please click the file name to download. Please reference the certification of compliance created in Document Center here. | |

| Import from Document Center | The referenced Certification of Compliance will be displayed in the column. | |

| Document Version | There are three types of the document version: Original Manufacture, Supplier and Buyer. | |

| File | The proof file of the Certification of Compliance. | Click the file name to download the file you reference. |

| Fill in Raw Material Information | Whether Raw Material Information is required to be filled once this document is refernced |

3. Edit Raw Material and Submit

| Column | Description | Remark |

|---|---|---|

| Create Raw Material. | ||

| Import Composition Datasheet into the Raw Material | |

| Copy Raw Material information from other MCD Survey | |

| Delete Raw Material | ||

| Sub Part Name | The subpart name of the part. | |

| Raw Material | The raw material of the part. | |

| Primary Source | Whether the Raw Material is a primary source | |

| Material Category | The material of the part, which can be categorized into several categories such as metal, plastic, chemical etc. Buyer can set the threshold limit for certain substances according to the subpart's category while setting the [Green Policy Settings]. | |

| Weight(g) | The weight of the subpart. Usually in gram(g). | |

| Exemption | The exemption for the subpart, selected only when there is/are substances in the Test Report that exceed(s) threshold limit, and is/are applicable for certain exemption. | |

| Material Original Maker | The Material Original Maker of the subpart. Such as CSC, Chimei, etc. The [Material Spec. and Material Original Maker] are a set of key info. which cannot be duplicated while creating a Composition Datasheet. | |

| Material Spec. | Click the Material Spec. to go to the editing page of the Composition Datasheet: [Basic Info.] | |

| Homogeneous Material | The smallest part of the material that can no longer be disassembled | |

| Confidential Composition(%) | The percent by weight of the Trading Secret in the Composition Datasheet. | |

| ICP Report No. | Click the ICP Report No. to go to the editing page of the Test Report: [Basic Info.] | |

| Compliance Status | The system automatically performs the compliance analysis of the [ICP Report] and [Composition Datasheet] for the subpart according to the Green Policy. | |

| Update Date | The last modified time. |

Edit Raw Material and Submit

Columns and Description

1. Fill in Basic Info.

| Column | Description | Remark |

|---|---|---|

| Sub Part Name | The sub part name of the part. | Required. |

| Raw Material | The raw material name of the part. | Required. |

| Material Category | The material of the part, can be categorized into several categories such as metal, plastic, chemical etc. Buyer can set the threshold limit for certain substances according to the subpart's category while setting the [Green Policy Settings]. | |

| Homogeneous Material | The smallest part of the material that can no longer be disassembled | |

| Weight(g) | The weight of the subpart. Usually in gram(g). | Required, should be greater then 0(g). |

| Exemption | The exemption for the subpart, selected when there is/are substance(s) in the ICP Report that exceed(s) threshold limit. | |

| Raw Material Policy | Buyer can set [Raw Material Policy] from [MCD Rule Settings] for certain subparts to apply, should the Green Policy is not applicable. Common raw material policies are for Packing material and Battery. |

2. Upload Composition Datasheet

The source of the Composition Datasheet referenced in the column is from Document Center-Composition Datasheet.

| Column/Button Name | Description | Remark |

|---|---|---|

| Material Spec. | The Material Specification of the raw material. For example: [ABS PA-757] for plastic and [JIS G3506 SWRH 42A] for spring wire. | Only one Composition Datasheet can be referenced. Click the Material Spec. to open the Composition Datasheet. |

| Create a new Composition Datasheet. The one created here will automatically be referenced. | Only one Composition Datasheet can be referenced. | |

| Rule Description | Hover mouse over to see the rule description | |

| Delete the Composition Datasheet referenced | ||

| Material Original Maker | The Material Original Maker of the subpart. Such as CSC, Chimei, etc. The [Material Spec. and Material Original Maker] are a set of key info. which cannot be duplicated while creating a Composition Datasheet. | |

| Homogeneous Material | The basic material from which a product is made and cannot be disassembled. | Click the Homogeneous Material to enter the Homogeneous Material page of the Composition Datasheet. |

| Document Date | The Document Date of the Composition Datasheet. | |

| File | The File name of the Composition Datasheet created from the Document Center. | Once referenced, you may click the file name to download the file. |

| Conflict Minerals Contained | Whether there are conflict minerals contained in this Composition Datasheet |

3. Upload ICP Report

The source of the ICP Report referenced in the column is from Document Center-ICP Report.

| Column/Button Name | Description | Remark |

|---|---|---|

| Click to view all substances required to be tested according to the Green Policy | ||

| ICP Report No. | The ICP report number of this test report. You may insert key words such as the report number and select it from the menu, or click the down-pointing triangle to select it from all of the [ICP Report]s created. | More than one ICP Reports/Test Parts can be referenced. |

| Display expired report | Check the box to display expired report while searching. | |

| Click to create a new ICP Report. | More than one ICP Reports can be referenced. | |

| Rule Description | Hover mouse over to see the rule description | |

| Testing Date | The testing date. As the report needs to be renewed every one or two years, the expiration date of this report is calculated based on the testing date. | |

| Test Lab. | The Testing Lab which conducts the testing, such as SGS, CTI .etc. | |

| Sample Name | The name of the sample which is being tested by the Test Lab. | |

| Sample Description | The description (model) of the sample which is being tested by the Test Lab. | |

| File | The File name of the ICP Report created from the Document Center. | Once referenced, you may click the file name to download the file. |

| Test Part | The part name of the sample which is being tested by the Test Lab. | |

| Revised No. | The number of the revised version of the ICP Report. | |

| Latest Version | Display whether the version of the revised ICP Report is the latest version. | |

| Category of Tested Item(s) | The Category of Tested Item(s) of the ICP Report. Such as RoHS2.0. |

4. Declare Guaranteed Substances

Check the box to declare that the part does not contain the substances in the list.

| Column/Button Name | Description | Remark |

|---|---|---|

| Click to view all the substances in the list that the the part [Guaranteed] not to contain. |

The Compliance Analysis Page

The source of the data referenced in the column is from [MCD Survey]

| Column | Description | Remark |

|---|---|---|

| Description | The description displayed in the column is/are the result(s) and reason(s) why the subpart is not compliant with the Green Policy after the compliance analysis. | |

| Reference | The ICP Report No. and the Test Part referenced in the subpart will be displayed in the column. | |

| Substance Name(En) | The Substance Name displayed in English. Buyer may require that the substances be [Tested] or [Guaranteed] for the part with certain threshold limit. | |

| Substance Name(Cn) | The Substance Name displayed in Chinese. Buyer may require that the substances be [Tested] or [Guaranteed] for the part with certain threshold limit. | |

| CAS No. | Chemical Abstracts Service, a unique numerical identifier assigned by the Chemical Abstracts Service (CAS) to every chemical substance. | |

| Control Level | The Control Level can be categorized into three types: Tested, Guaranteed and Monitored. Tested: The substance is required to be tested. Guaranteed: The substances is not required to be tested, while the supplier needs to guaranteed that the part does not contained the substance. Monitored: The substances is not required to be tested or guaranteed. | For Control Level [Monitored], the substance does not need to enter Test Result. |

| Threshold | The threshold limit of the substances that meets the Green Policy requirement. | |

| Report Test Result | The Test Result of the substance(s). Detected: YES, provided the tested result. Not Detected: N.D. | |

| Report MDL | Method Detection Limit, the minimum measured concentration of a substance that can be reported with 99% confidence that the measured concentration is distinguishable from method blank results. | |

| Report Unit | The unit that is used to calculate the test result for the substance. Such as ppm, ug/cm², ug/m²/week, mg and ug/m². ppm and µg/cm² are commonly seen. | |

| Composition % | The Percent(%) by Weight of the substance in the Composition Datasheet. | The column will only display data when the buyer is engaged in the FMD. |

| Composition ppm(mg/kg) | The Percent(%) by Weight of the substance in the Composition Datasheet converted to ppm(mg/kg). 1% = 10000 ppm. | The column will only display data when the buyer is engaged in the FMD. |

You may use the filter

to search for certain substance.